Managing Equipment Breakdowns with Digital BDM System in Pharma

In the fast-paced pharmaceutical industry, equipment reliability is crucial for maintaining production efficiency and regulatory compliance. Yet, many companies still depend on outdated, paper-based tracking systems that slow down repairs, increase downtime, and compromise data accuracy.

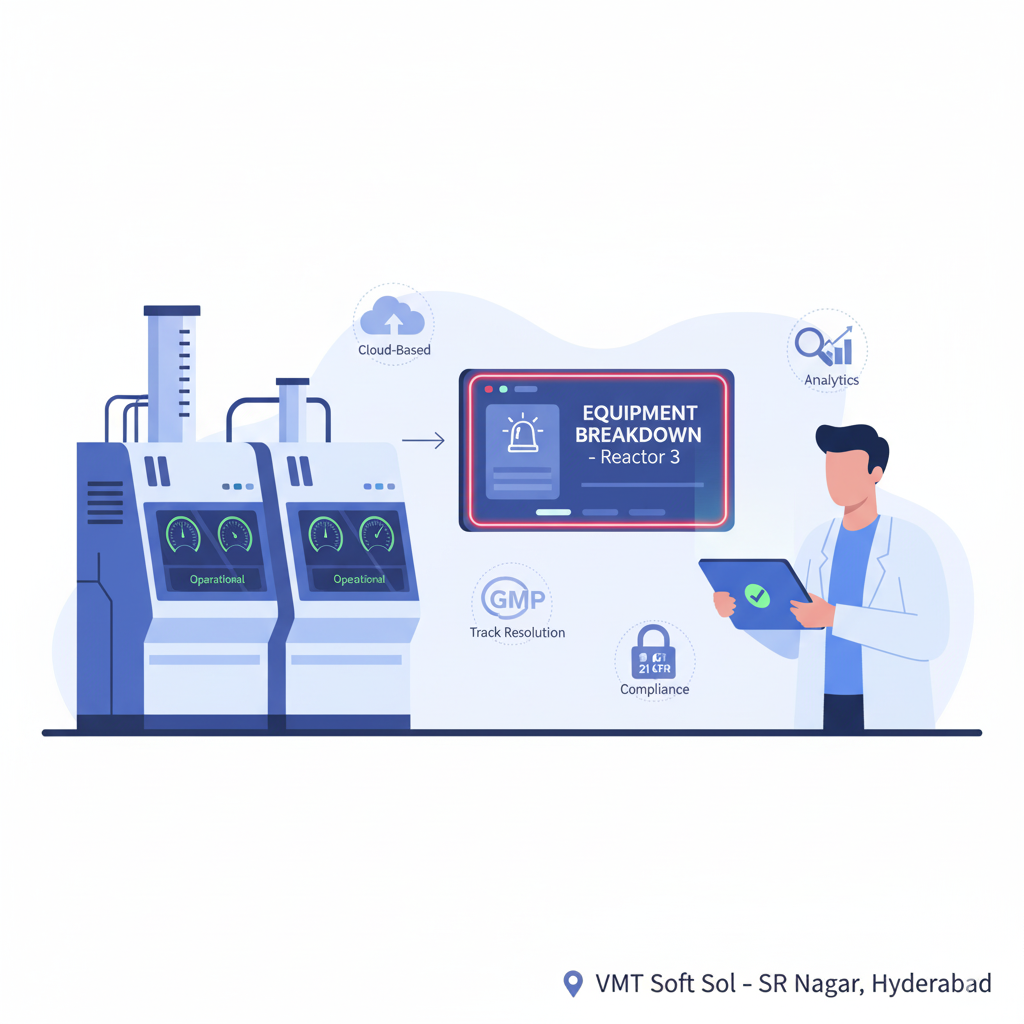

A Digital BDM System offers the solution — automating breakdown reporting, approval workflows, and maintenance tracking to keep operations running smoothly and compliant.

The Problem: Manual Breakdown Tracking Causes Delays

Manual Equipment Breakdown Tracking in Pharma environments creates significant bottlenecks in maintenance and compliance. Here are the most common challenges:

The Solution: Digital Breakdown Management System for Pharma

Implementing a Breakdown Management System Pharma digitizes every aspect of the maintenance process — from problem detection to resolution. It ensures every request follows a transparent, automated workflow that accelerates approvals and guarantees accountability.

Here’s how it works:

The Benefits of a Digital BDM System

Switching to a Digital BDM System offers measurable results that directly impact efficiency, compliance, and product quality:

Reduced Downtime: Automated alerts and approvals minimize time between issue reporting and resolution.

Reduced Downtime: Automated alerts and approvals minimize time between issue reporting and resolution. Regulatory Compliance: Fully aligns with GMP Compliance Software India standards and other regulatory guidelines such as USFDA, MHRA, and WHO.

Regulatory Compliance: Fully aligns with GMP Compliance Software India standards and other regulatory guidelines such as USFDA, MHRA, and WHO. Centralized Equipment Data: Track performance, history, and usage across multiple plants from one platform.

Centralized Equipment Data: Track performance, history, and usage across multiple plants from one platform. Improved Audit Readiness: Generate accurate, timestamped digital records for effortless audits.

Improved Audit Readiness: Generate accurate, timestamped digital records for effortless audits. Cost Efficiency: Eliminates paper waste, reduces maintenance costs, and maximizes resource utilization.

Cost Efficiency: Eliminates paper waste, reduces maintenance costs, and maximizes resource utilization. Predictive Maintenance: Data analytics highlight equipment trends, helping prevent future breakdowns.

Predictive Maintenance: Data analytics highlight equipment trends, helping prevent future breakdowns.Why Indian Pharma Companies Need Digital BDM Software

For pharma manufacturers across Hyderabad, India, and beyond, adopting a Breakdown Management System Hyderabad ensures continuous equipment reliability and compliance. It simplifies cross-department coordination, automates documentation, and enables seamless integration with existing systems such as QMS, LIMS, and CMS.

By implementing Pharma Software Solutions India, companies gain complete visibility over breakdowns, enabling faster decision-making and operational excellence.

VMT Pharma Soft Sol’s BDM Solution

VMT Pharma Soft Sol Pvt. Ltd., based in Hyderabad, India, has developed a comprehensive Breakdown Management Software designed exclusively for the pharmaceutical and life sciences sectors.

The system automates breakdown tracking, service scheduling, and root cause analysis while integrating with modules like Calibration Management, CAPA, and Audit Management.

Whether deployed on-premise or via the cloud, VMT’s Breakdown Management System Pharma empowers organizations to minimize downtime, improve compliance, and achieve sustainable operational efficiency.

Conclusion: Minimize Downtime. Maximize Compliance.

A reliable Pharmaceutical Equipment Maintenance Software ensures your facility stays audit-ready and production-ready. Moving from manual logs to a Digital BDM System means fewer disruptions, better compliance, and more predictable performance.

Book a Demo today and discover how VMT Pharma Soft Sol can help your pharma business achieve efficiency and regulatory excellence.

VMT Soft Sol Pvt. Ltd. specializes in eQMS Software for the pharmaceutical industry. We simplify compliance, enhance efficiency, and ensure operational excellence.

# 8-3-167/A/52, 2nd Floor, Vani Nilayam, Vikaspuri, AG Colony Road, S R Nagar(PO), Hyderabad-500038.

Phone Number : +91-9866968830